This article is one of a 16-part series on the fundamentals of stamping. Descriptions of all the articles in this series, and links to them, can be found at the end of this article.

|

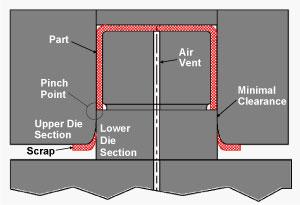

| Figure 1 Pinch trimming die design |

Various specialty metal cutting methods are used in stamping operations. Among them are pinch, breakout, and shimmy.

Pinch Trimming

Pinch trimming is a special method in which the vertical walls of a drawn or stretched vessel are cut by pinching the metal between two hardened tool steel die sections. In most cases, the clearance between the die sections is as little as possible (Figure 1).

Unlike a conventional metal cutting process, no shearing or fracturing takes place in pinch trimming. Items such as deep-drawn cans often are pinch trimmed.

Although pinch trimming is a very popular method, because the metal basically is pinched off, a very sharp burr usually remains on the part (Figure 2). This burr must often be removed by tumbling the parts in a tub containing abrasives.

|

| Figure 2 Result of pinch trimming |

Pinch trimming also places a great load on the sides of the die sections, which results in high wear. Most pinch trimming operations require a great deal of maintenance.

Breakout Trimming

Breakout trimming is a specialty metal trimming process in which the metal is forced to fracture or break free from the vessel's flange. If you are accustomed to conventional cutting operations, this process most certainly may look harebrained to you. Unlike a conventional metal cutting process, the lower die section has a 45-degree angle ground on its edge. This angle has two basic functions: first, to allow the cup to fully nest in the lower die, and second,. to force the flange to bend upward slightly.

The cutting clearance also is much greater in breakout trimming than the clearance commonly used in conventional cutting operations. This additional clearance causes leverage action, but does not allow for the metal to be bent into a vertical wall. However rest assured, this process works well, especially for metals that severely work harden (Figure 3).

|

| Figure 3 Break out trimming |

Breakout trimming takes advantage of the metal's work hardening and reduced thickness in a given localized zone. This method works best for round or axial symmetrical drawn parts.

For breakout trimming to work effectively, the drawn cup must be properly prepared for the process. The inside radius on the cup's flange must be reduced to a dead sharp corner before using this method. This is achieved by drawing the cup deeper in the drawing operation or compressing it back over a dead sharp corner on the die section (Figure 4). Doing so reduces thickness in the radius and allows work hardening to take place.

|

| Figure 4 Creating a small radius |

After the cup has been prepared properly, it can be introduced into the breakout trimming process, in which the cup flange will be forced upward, causing the metal to breakat the dead sharp corner (Figure 5). Because the cup flange is round, as it is pushed upward it is forced into radial compression. This compression works to your advantage by forcing the cup to be fractured out of the flange.

Breakout trimming does not produce a burr as large as that produced by pinch trimming. Also, because the loads on the tool steel sections are minimal, the die requires less frequent maintenance. However keep in mind that this method can be used only in situations in which the metal must be cut at the intersection of the flange and the cup's vertical wall.

|

| Figure 5 |

Shimmy Trimming

Shimmy trimming is a unique metal trimming process in which a series of specially designed cams are used to force the part to move side to side. Unlike conventional cam trimming, the part does not remain stationary, but rather moves horizontally in the die. It moves in such as fashion that it can be trimmed true to the surface of the vessel. Trimming 90 degrees or true to surfaceresults in a much cleaner cut and considerably lower burrs than pinch trimming.

A great advantage of shimmy dies is that they can cut the entire perimeter of a part in a single press stroke. Unlike conventional pinch trimming, a shimmy trimming operation is not restricted to straight line cuts. Features such as notches, curved cuts, as well as a various other cuts can be made. Many common items such as cigarette lighters and gun shells are made using the shimmy trimming process.

|

| Figure 6 Parts trimmed with a shimmy trim die Images courtesy of Vulcan Tool Corporation |

Shimmy trimming operations also can be designed to cut metal as thick as 0.250 in. and, unlike conventional pinch trimming, can keep the original metal thickness in the trimmed area. Not like conventional cutting operations, shimmy dies require a pressure system such as a press cushion or a nitrogen gas manifold (Figure 6).

Which metal cutting operation a die design engineer chooses is based on many factors, including allowable burr height, parts volumes, metal type and thickness, and trim line geometry. No single trimming operation is best for all scenarios. The next article in this series will continue the discussion of metal cutting.